Alphaseptic Acoustical Ceiling Tiles

Good acoustics and sanitary conditions are critical in food

prep and point of sale areas.

First step in acoustic remediation is to determine

empirical reverberation time in the concerned area.

Measured reverberation indicates architectural

contribution to noise.

A leading source of noise in high technology clean rooms is

attributable to ventilation systems due to large volume

airflow. Alphaseptic modules may be utilized internally in

HVAC systems or acoustically engineered to retrofit for noise

remediation.

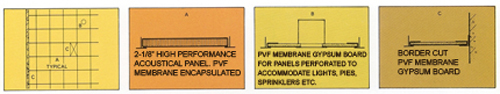

It is easily cleaned with ordinary cleansing agents. It remains tough and flexible from -100°F to 225°F to absorb almost any form of impact without physical degradation. Alphaseptic acoustical ceiling panels will provide years and years of service without cracking or peeling. They have received the U.S. Department of Agriculture's approval as a component of ceilings and walls in meat or poultry preparation areas. Our unique method of totally encapsulating the acoustical material assures a complete seal to prevent fiber migration. Alphaseptic panels fit into standard suspended grid ceilings. Standard sizes are 24″ × 24″ and 24″ × 48″. Special sizes are also available.

Where fitting and trimming is necessary, we provide border panels of 1/2″ gypsum board with the same PVF membrane covering. This allows a uniform ceiling finish while providing superiro sound absorption in areas where acoustical materials could not be previously used. Additionally, Alphaseptic Ceiling Panels may be used as functional absorbers or as encapsulated media in Alphaloc Silencers for fants, blowers or HVAC systems. Application engineering is available.

| Before | ||||

|---|---|---|---|---|

| Surface | Material | Area | Coefficient | Sabines |

| Ceiling | Plaster on concrete | 8144 | 0.02 | 162.88 |

| Floor | Quarry Tile | 5631 | 0.02 | 112.62 |

| Walls | Glazed Tile | 3543 | 0.02 | 70.86 |

| Windows & Lights | Glass | 316 | 0.03 | 9.48 |

| Production Equipment & Working Surface | Stainless Steel | 3585 | 0.01 | 35.85 |

| A1 = 391.69 | ||||

| After | ||||

|---|---|---|---|---|

| Surface | Material | Area | Coefficient | Sabines |

| Ceiling | Plaster on concrete | 8144 | 0.02 | 162.88 |

| Floor | Quarry Tile | 5631 | 0.02 | 112.62 |

| Walls | Glazed Tile | 3543 | 0.02 | 70.86 |

| Windows & Lights | Glass | 316 | 0.03 | 9.48 |

| Production Equipment & Working Surface | Stainless Steel | 3585 | 0.01 | 35.85 |

| 795.61 | ||||

| Minus wall area lost from installation | -7.60 | |||

| A2 = 7958.01 | ||||

Reduction in Decibel = 10 log10(A2/A1) This example = 10 log10 (7958.01/391.69) = 13.08 dB

The addition of ALPHASEPTIC Ceiling Panels creates a 13.08 Decibel reduction.